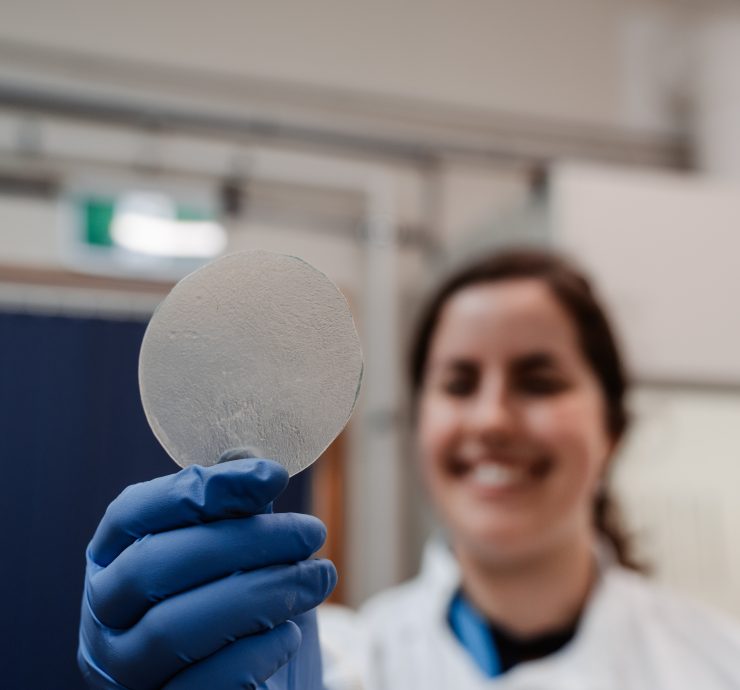

Lincoln Agritech’s New Materials team has developed a breakthrough bioplastic that could replace single-use plastics in healthcare.

While working on a process for developing cellulose fibres, Lincoln Agritech Research Assistant Erica Sue-Tang had an idea.

“While I was working with the team on cellulose fibres, it sparked a thought, what if we could take it further and create a new cellulose-based plastic?”

That question led to a material that shows promising strength compared to common bioplastics and could offer an alternative to conventional plastics, without the environmental and health risks.

Hospitals and home healthcare rely on millions of single-use plastic items like ostomy bags, glucose sensors and dialysis tubing.

These plastics don’t break down and can shed microplastics, even during and after sterilisation.

Those particles may enter the human body, and while research is still emerging, early signs point to potentially serious health risks.

“Common petroleum-based plastics aren’t renewably sourced or biodegradable and millions of tonnes end up in the environment, creating microplastics,” says Erica.

Currently available bioplastics aren’t the solution, as few are biodegradable.

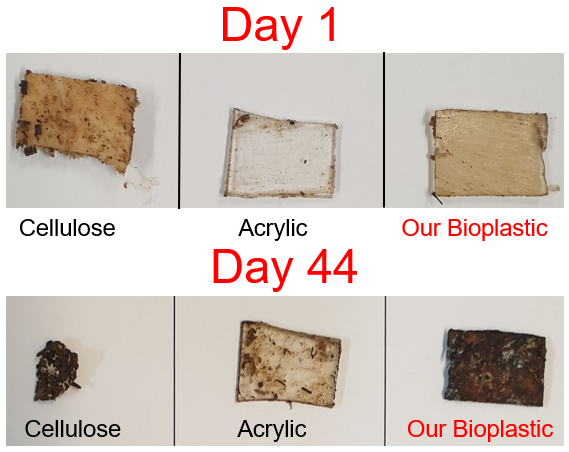

Unlike fossil-based plastics and even some bioplastics like PLA, the new material Erica is working on is biodegradable, recyclable, and microplastic-free, even after sterilisation.

“My idea is a cellulose bioplastic made using renewable resources, which biodegrades into sugars in natural environments.

“We wanted to create something that could meet the demands of healthcare, but without the long-term harm,” she says.

The breakthrough bioplastic Lincoln Agritech has produced is made from natural cellulose and processed using a patented solvent system. It’s strong, moisture-resistant, and suitable for sterilisation, ideal for packaging items like glucose sensors, dialysis bags, and other home healthcare products.

Erica pitched the concept at Falling Walls Lab, a global competition for world-changing ideas, where her presentation “Breaking the Wall of Biodegradable Bioplastics” reached the national finals in Wellington.

The innovation has global relevance as regulators crack down on microplastic pollution. The EU will ban synthetic polymer microparticles by 2029, and the US Microplastic Safety Bill, which would require the FDA to report on the health impacts of microplastics, is currently going through the legislative process.

Next steps, Erica says, include developing and testing prototypes, and collaborating with hospitals and private companies to bring the material into practical use.